The Latest

-

If you've been around cars and trucks very long, you know that vintage, nostalgia, and rat rods are very popular.

March 21, 2009 -

One of the most frustrating things that can happen when you are bulding a project is finding out the parts you need are no longer available.

April 11, 2009 -

When it comes to classic hot-rod components, nothing gets people going like a multi-carb setup. And the king amount these is the Tri-power.

March 29, 2008 -

Stacey pulls out the tools and starts working metal as he dives into the subject of what to do when your floors are gone... I mean literally gone... nothing there!

April 12, 2008 -

Stacey takes a look at one of the first aftermarket parts that became available to the public back in the day. The performance air filter, and man does it have an interesting story!

May 31, 2008 -

Ya know, people are always asking if it is possible to get their rig on GearZ?

June 07, 2008 -

Stacey puts the finishing touches on the '07 Jeep Wrangler with off-road bumpers, body armor, and some off -road lights, and builds a very capable off-road rig that is still civil enough to be driv

June 22, 2008 -

Stacey takes a well worn, '73 Chevy pickup that was left for dead in the late 80's, and starts bringing it back to life by upgrading the suspension and brakes.

February 21, 2009 -

Stacey jumps back into the "KnuckleBuster" project and deals with an area we can all relate to...a sick engine and transmission.

February 28, 2009 -

Everybody knows that the area most prone to wear and tear on your vehicle is the interior.

March 07, 2009 -

Hey! What is the most important part on your project?July 21, 2007

-

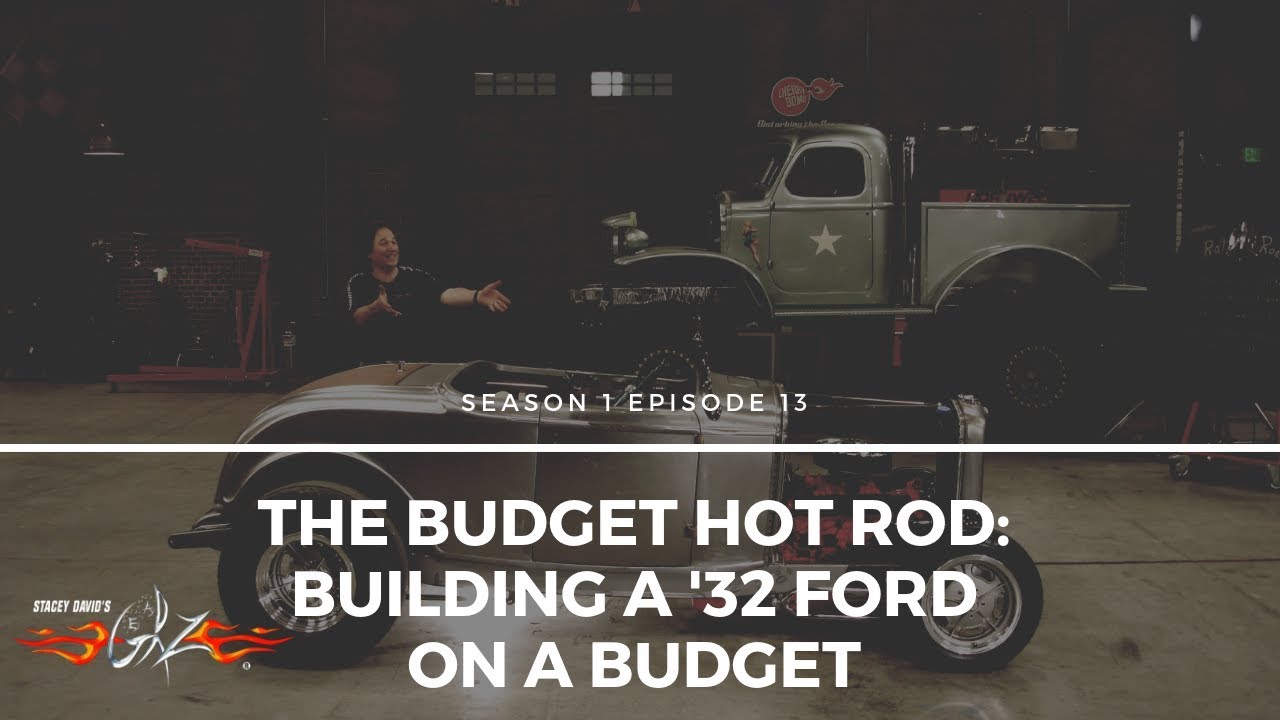

Stacey deals with one of the most talked-about issues facing the hot rod hobby-COST! Then he shows you that it is actually possible to build a steel-bodied ‘32 Roadster for around 20 grand.June 23, 2007

-

There is no doubt that the '32 Ford is one of the most legendary cars ever built.June 16, 2007

-

Its a real world, working man's truck where Stacey shows you how to take a late model diesel pick up and make it better, stronger, and tougher than it was before...and its something that can be done iJune 09, 2007

-

Quick... when it comes to performance exhaust, what is the first name that comes to your mind? If it is not Cherrybomb, then you've missed out on a lot of years of disturbing the peace...June 02, 2007

-

Today on GearZ, the Banshee gets a major face-lift as Stacey transforms it from a Mazda Miata into a...well...uh...the Banshee!!May 26, 2007

-

Stacey digs into a project that shows you just how much fun you can have for almost no money...because he's taking a derelict 70's ATV...stuffing in a junkyard engine...tossing in some good ol' AmericApril 08, 2007

-

What do you get when you cross the quintessential girl's car...the Mazda Miata...with the ultimate guy's car...the Shelby Cobra???April 14, 2007

-

Last week, he made room...this week, the transplant takes place as Stacey stuffs a 400 horsepower V8 into a Mazda Miata.April 21, 2007

-

Stacey takes you for a unique spin in one of the largest 4-wheel vehicles ever built...the Larc 60.April 28, 2007

-

This is a show for all you restorers out there because Stacey not only shows you how to properly drive your hot rod by flogging on a '70 Superbird...he also shows you some tips and tricks on restoringMay 06, 2007

-

It's anniversary time! The '32 Ford is 75 years old and we take a look back at what made this car so popular for so long.May 13, 2007

-

The Banshee is back on GearZ and rollin' down the final stretches as Stacey installs new suspension and brakes to help control this molten missile when he uncorks that nasty V8.May 20, 2007