Submit your project

You and your project could be featured on the show earning you cool prizes from our sponsors. Check out past WAYWO features below.

"What Are You Workin' On?" Partners

Heck Industries was established in 1966 as an inventor and manufacturer of unique cost saving metal working machinery.We soon became the world leader in plate beveling machines.

Mouse Blocker has a complete product line of solutions developed specifically to protect your vehicle and equipment from the costly damage caused by mice and other rodents including rats, squirrels

What Are You Workin' On?

Season 19: Episode 13

Jeff St. Clair | Rockwood, PAMy wife always wanted an old truck. I told her that we couldn't afford one. But then my son-in-law came across this rolling chassis from a 1926 Dodge Brothers pickup. He told me that I could have it and do anything I wanted with it. A friend saw it and told me his brother had a flathead V8 from a 1950 Ford F-1 truck and I should call him. His brother, also a friend of mine, gave me the engine. It had been in his dad's old truck. Once we knew the engine would run, I started the fabrication. This truck is built mostly from things I had laying around my house. The grill is from a steam oven from the hospital where I worked as a maintenance man. The bedsides are from an elevator shaft from that hospital. The tailgate is from an X-ray machine. The curves in the hood and the cowl are from Freon tanks. A friend gave me the steel for the floor and where the cab sits. I had to buy steel for the roof and cab because junk guys just don't have that big of pieces laying around. The gas pedal is from a drum set. There's a cutoff switch that a friend gave me. The steering wheel is from a 1961 Jeep pickup that I hauled coal with when I was a kid. The radiator was junk. I bought a Champion radiator for the flathead V8, a rebuild kit for the carburetor, and a tune up kit. I had to rebuild the fuel pump. There were 2 stuck valves that weren't a problem to get unstuck. And we've got the engine purring like a kitten. I also had to buy 2 new rear tires as they were completely shot, but the front ones were ok. I have just over $3000 in the whole custom rebuild. The seat is from a Ford Bronco that was given to me by a friend. I did almost all the fabricating myself with some help from my son-in-law and grandson. The whole build took just a shade over two years.

Season 19: Episode 12

Eddie Baxley | Venus, TXI’m submitting my El Camino to show you don’t have to start from scratch to have a cool project. I had a 2013 GMC Sierra 1500 SLE, and I traded it for this El Camino plus a good deal of cash. However, both the seller and I walked away feeling we got a good deal, which is what any good deal is all about, right? Anyway, the car/truck was almost fully restored and was driven for about 30,000 miles. However, the restoration wasn’t frame-off, there were still things left to do. That’s where my project comes in. I named her Ellie (for a couple of reasons, 1. it’s an El Camino and 2. my granddaughter’s name is Emily, who is often called EL.) and she started life as 307 Custom. Obviously 350 badges were added and the guy I got it from says the motor is a 350, and it feels like he’s correct when I step on it.

The suspension, while it was rebuilt, was rebuilt stock. So, that’s where I’ve started. I’m adding air shocks to the rear so I can actually use it to tow my motorcycle, and I’m adding a rear sway bar as well. I’m changing that weak 15/16” front sway bar for a QA1 1 1/4” sway bar and Bilstein front shocks to make it handle like it should. Plus, I’m adding a front disc brake conversion kit, so it’ll stop when I want it to. I’m also changing the steering worm gear from stock to a 10-1 ratio, so it’ll feel a little more modern and have better response.

I plan to do more as I have time and money, but after the suspension work is done, the next big thing is adding AC, since that’s the one thing it was missing. I plan to change out the bench seat to a console type bench that sits you further back and holds you in the seat better. That may be my biggest challenge. I also plan to change the TH350 tranny to a 700R4 so I can get better gas mileage on the highway, because I do plan to drive this. The cool thing is I’ll be able to drive it to either car shows or bike shows and show them both off.

Obviously, this is a long-range plan, but it’s really only dependent on time and money. Finally, I’m 70 years old, so I don’t plan to do all the work myself, but I will do some and have already done some, it just depends on my comfort level of what needs to be done. So, I didn’t submit this for recognition or for free stuff, it’s mainly to show that you don’t have to start from scratch and you don’t have to be young to do it either. But it does help to be young at heart, which technically I’m a big kid at heart. LOL!

I waited for several years to find someone who was willing to trade for my truck and that had the El Camino in the shape I was looking for. I believe (while it required much patience) I had divine help. I actually drove it home for a couple of hours when I bought it. Without AC I did get hot and I was ready to get home.

Season 19: Episode 11

Mackenzie McDaniel | Montreal, MOI’ve decided to rekindle an old flame… This 1969 Chevrolet C10, named The Orange Truck, became my first vehicle over twenty years ago. My folks and I found the blue-green Chevy in a barnyard while running backroads one afternoon. We pulled in the nearest driveway and lucked out to find an owner who was willing to sell. $1,200 and a week later, we had it on the trailer and headed home. We stripped it down and went through the truck from front to back. We had a buddy paint it 1971 Carousel Red and white. Who doesn’t love GTO Judge Orange? Dad and I found it had a stout drivetrain in place that just needed a few gaskets, much to our surprise. It had a Comp roller cam, Edelbrock Performer RPM intake, Holley 750, and 0.050 over flat tops to name a few of the goodies we found when we cracked the 350 open.

About a year later, we had a very nice-looking truck for a 16-year-old that was probably a little faster than necessary. Interesting side note: ‘69 C10 speedometers will wrap around if you were wondering, but things get pretty loud and bouncy when that driveshaft carrier bearing gives out when testing those limits. Fast forward through high school, college, and life, the poor Orange Truck faded out, dried out, and rusted out from neglect. With the urging of my (Ford loving) wife and 10-year-old nephew, we’ve made the ‘69 the latest family affair. My nephew has learned how to clean a project vehicle inside and out, remove the seat and carpeting, replace fuel lines, and change the fluids. He even learned how to replace drum brakes, lines, and wheel cylinders. He helped me bleed the brakes.

My two-year old daughter has helped in her own way too! She heads straight for the shop anytime we’re outside, and grabs whatever tool is within reach to help Daddy out. I’m hoping to use this project to show my nephew proper vehicle repair and maintenance techniques while fueling a love for old Chevy trucks. I also hope to form fond memories for my daughter as she grows up cruising in it together as a family. If she becomes a Chevy girl because of this truck, that’s just an added bonus! We still have to replace the rusted driver’s floor pan and cab mounts, freshen up the interior, and take some age out of the wiring. We’ll get it cruising this summer, then bring it back in this winter for upgraded suspension and brakes, fuel tank relocation out of the cab, and final body work that we don’t have done yet. I bought this truck just before Copperhead was being built and was inspired by all of the Trucks! episodes back then and by Gearz today. Thank you for the knowledge, inspiration, and encouragement throughout the years!

Season 19: Episode 10

Adam Taran | Denver, COI have been watching Stacy since I was in college, and when I turned 40 I decided to do a dream sleeper car. I always wanted to build a radical sleeper car with original patina, and I saw this one on Facebook marketplace with a solid chassis for $700 with a spun rod bearing and fell in love with it. Also, because as far as I can tell no one has ever stuffed a turbo V8 engine into a B12 Sentra.

I used this project to teach myself metal fabrication skills such as MIG welding, chassis and exhaust fabrication, and roll cage design and fab. Prior to this, I did mostly bolt-on parts and built a DF Goblin kit car. I had spinal fusion surgery halfway through this project and used this car as motivation make it through recovery. I worked on CAD design and engineering and interior parts during surgery recovery.

This car is street legal, and I plan on cruising to car shows and car clubs, LS fest, and Radwood. I also want to hit the drag strip and try to get into the 10s, and maybe do some autocross since the car is riding on fully adjustable coil-overs and Mazda Miata suspension with upgraded bushings.

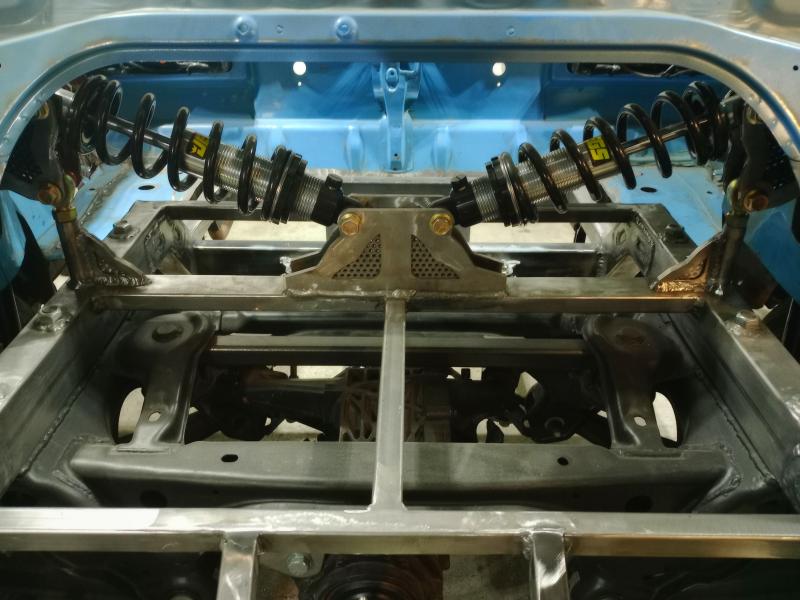

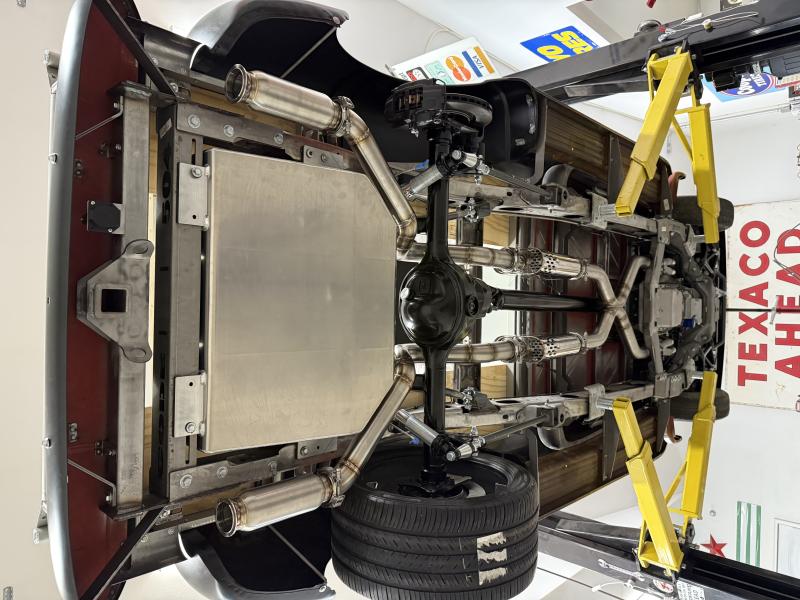

It’s a 1988 Nissan Sentra 2-door sedan. I cut out the entire floor and firewall and grafted in 2004 Mazda Miata subframes and complete suspension. The front subframe is the V8 Roadsters Miata V8 swap kit and the rear end is a Cadillac CTS differential Miata kit with forged rear hubs and 650HP driveshaft shop axles. It also has a 1,000HP Action Machine driveshaft. I built cantilever rear suspension and a roll cage with door bars. It has a 10-gallon fuel cell in the trunk floor. I am saving up for the engine now – a 5.3LS with 78mm turbo, air/water intercooler, and Cobra Mustang intercooler pump. I changed the front suspension to double wishbone from McPherson strut and had to rebuild the strut tops 6" lower. I pushed the firewall back by 8". Holley Terminator ECU with digital dash is the plan. It has Wilwood 4-piston big brakes in front to stop, a Tremec TKX 5-speed trans, stock seats with PRP harnesses, a racing pedal box with remote reservoirs, coil relocation kit, and a GP Headers single turbo kit with front crossover. The power goal is 600 rear wheel HP. I have made 166 CAD drawings thus far, and lots of custom laser cut and welded parts. Fab is 95% complete and I will be moving into chassis paint next. Exterior is staying patina. I went to great lengths to make sure the hood closes.

Season 19: Episode 9

Johnny Thompson | Pell City, ALMy son worked all summer cutting grass to buy a 1964 Chevrolet Impala 4-door hardtop from his uncle in 1988. He drove it to high school until he graduated and two years after. He decided then that he wanted a new car, so he bought a new Camaro and the 64 was parked beside our house in the woods. Needless to say, he lost interest in it for a while, and it sat on that hill for almost 12 years. At that point he started bugging me to restore it. In 2013 we started building a shop with the plans that once the shop was finished, we would start the ‘64 build.

My son was diagnosed with cancer in 2015, and in January 2016 he passed away. In keeping with his wishes, I pulled the ‘64 out of the woods in April 2016 and the journey began. After getting the ‘64 out of the woods, my heart just sank because it didn’t look like it was worth restoring at the time, but with encouragement from my wife and his circle of friends that knew the history of the car, I committed to the task of restoring his ‘64 Impala.

Upon initial inspection, I found that the floor pans, trunk pan, fenders, hood, and trunk lid had to be replaced. I tore it down to the point that the body was just a bare hull, took it off the frame, and restored the frame. I replaced all bushings, tie rod ends, ball joints, idler arm, and the pitman arm, and built the rear end. I sanded the frame by hand and sprayed it with a rust preventative and then painted it black.

The window chrome, and the lower window frames were rusted beyond repair, so in 2018 I bought a donor car just for the hard-to-find parts. The taillight sockets were rusted out, so I cut them out and welded new ones in. I sanded the body down to bare metal and built a paint booth out of plastic in my shop and primed and painted it myself. It’s the first car I ever painted, and it looks great! It has been a lot of firsts restoring the ‘64. I built the little 283 and the Powerglide transmission. The 283 is on steroids. I am coming to the end, and I should be finished in 6 to 8 months. I’m waiting on carpet and seat covers, and when they are installed, we will be ready to ride and show it off.

That’s what my son wanted and it’s going to happen! It has been a labor of love, and I have enjoyed it so much that I got a 1987 Chevy Squarebody truck that’s going to be next. You will never know how many times that I wished I had not put my son off when he wanted to start the ‘64 build. What I have learned from this is never take for granted what you have because you never know when it may be taken from you. Our son was a wonderful Christian man who loved God, his family and his 64!

Season 19: Episode 8

Chris Hollerback | Arvada, COAfter a 40-year hiatus from custom car building, I took 3 years to build a Restomod 95 F150 that will be the Cover Truck for LMC’s 2nd quarter catalog.

While building this project, I was approached by a neighbor regarding an opportunity to replicate a Prowler Concept vehicle that was supposedly crushed by Chrysler.

This neighbor had a Prowler that was damaged in the rear that would be a great challenge to replicate the Concept Car.

Challenge accepted!

The Concept was a truck version of the Prowler Roadster which was built with a removable hardtop. Beyond recreating the Concept truck bed, I was challenged to incorporate the ability to stow the retractable soft top.

The tailgate was fabricated from a Ford Ranger tailgate that I had to chop 7” and modify the crown to match the curvature of the fiberglass panels I also fabricated.

The side panels and rear fenders are a work in progress. A new frame was located and purchased, and the fabricated fiberglass will be completed after the body swap. The dual articulation of the rear deck and fabricated tonneau was a successful achievement!

This neighbor is now a close friend and intends to keep the “Howler” and show it at national Prowler events.

We still have a way to go!

(First photo is the Actual Concept Car and what we are replicating)

Season 19: Episode 7

Alex Penor | Billings, MTThis is a 1949 Chevy pickup originally sold new at Penor's Chevrolet later became Penor's Texaco in Bison, SD. My great-great-grandfather Harry Penor sold the pickup to a gentleman; I believe his name or nickname was Red. At the time of the sale my great grandfather Dean Penor, Harry's son, mentioned to Red that if he were to sell it, he would like a chance to buy it back, and about 3 years later he did. Since that time, my grandmother Gloria and her sister Vera learned to drive in it, followed by Gloria's two sons Robby (my dad) and Roger. My great grandfather Dean ran Penor's Texaco up to 2016 working everyday into his mid 80's. Since I was the only professional mechanic left in the family, my great grandfather, my dad, and I started the transformation. We started with the pickup and a 2012 Camaro 6.2L, 6L80, two S10 pickup frames, and a code 504 kit. We split the C-channel frames and welded them together to box in the frame, added a 4-link rear end with a 9-inch Ford from QP, and aftermarket upper and lower control arms in the front with coil overs all around. Brakes are the 14-inch Brembo off the Camaro with an electric e-brake from a late model Corvette. A new floor and firewall were fabricated by my dad and myself with aftermarket inner fenders. At this point we are just completing the 3-inch stainless exhaust. Next, it’s the wiring harness then it’s off to body and paint. So far this has been a 6-year journey. We lost Dean in 2021, and the build is dedicated to him.

Season 19: Episode 6

Michael Harding | Menifee, CAI bought my 1965 Plymouth Belvedere II in 2001 as an all-original cruiser and am technically the second owner. I even have the original 1965 dealer frame on the rear license plate! I did a few minor upgrades like a four barrel and intake, cleaned it up a bit, replaced a few bent/twisted things, then I took it to Willow Springs on a whim. My only upgrades were an A-body front disc brake upgrade, a dual quad FAST EZ-EFI, and a set of Hellwig sway bars. On one lap, I found myself catching the tail end of a Porsche Carrera coming out of the fast sweeper (Turn 8).

It became a magazine project car, and I started doing upgrades and going back to Willow Springs to report on my improvements. After 7 trips, I was a little over 10 seconds faster around Big Willow than when I started. By then I had a full coil over suspension, big brakes, fat tires, and was still running the EZ-EFI but on a single setup. I was still catching Porsches and caught a Cayman GT in the tightest part of the track.

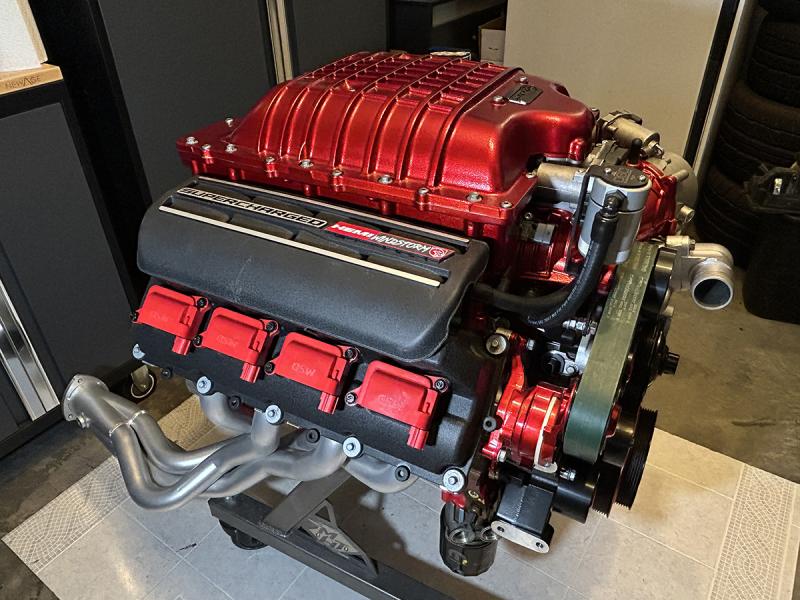

I was supposed to have a new Stroker Small Block built, but two shops jacked everything up; the first shop delivered the fresh build with no oil to the cylinder heads, and left a key plug out and I had no oil filtration. I tore it back down to the bare block, bought new parts, took it to a different shop, and he delivered it with less than 5psi at idle. So, the car sat for a while so I could figure out what to do next, then an opportunity presented itself to me: I bought a wrecked Hellcat Redeye, and plan to install that drivetrain, hopefully this summer. I tore the engine down to the long block, did some painting and detailing, and added some aftermarket/performance parts, and am just about ready to start on the Hellcat Swap.

I renamed the project "Windstorm" and got my personalized "Hellvedere" vanity plates (HLVDERE). I still need to get a few more things together, but it's close. I even designed new Dakota Digital gauges (HDX) to mimic the Hellcat Redeye gauges.

Season 19: Episode 5

Deryl Sewell | Colleyville, TXI'm 71 years old and this Chevy C10 truck belonged to my grandfather. He died in 1980. My grandmother sold it in 1981. Eighteen years later I tracked it down and bought it back. I've taken it down to the frame and over the past 8 years, restored it with upgrades like a 350 V8, 700R4 trans, power everything, CPP suspension, disc brakes, etc. My granddaughter wants the truck, even though she has new automobiles. So, it will go to her mother (my daughter), then to her. Gearz helped me build this truck. I watched hours of episodes to learn to do so much of the restoration. And my project planning book was invaluable. Thank you for all you do and please keep the shows coming.

Season 19: Episode 4

Talbot Smith | Albuquerque, NMThis is the life story of my dad/mom’s car, the 1966 SS396, that he ordered through the "GM Military Discount". Once he got his orders to come home, he grabbed the order sheet and proceeded to check 21 for his car. Dad said that the FIRST option he checked was Air Conditioning, because of having spent the last year in Vietnam under the most oppressive heat/humidity that he ever saw! The rarest option that he specified was the 3:07 gear ratio for the positraction rear end (3:31 and 3:73 was the standard choice), due to knowing that we were going to be immediately heading East on Route 66 to MCAS Cherry Point, North Carolina after we took delivery at Guaranty Chevrolet (Still there!) in Santa Ana, California.

My mother, sister, and I were sent by my dad to live in Fukuoka, Japan near mom’s relatives, just in case dad didn’t make it back, but in August 1966, we all met back at LAX airport. I remember the rental car we picked up at the airport. It was a gold 1966 Dodge Dart with a black vinyl top. When we arrived at Guaranty Chevrolet (just a little way from Angels Stadium), our salesman had dark sunglasses, red hair, a black jacket, white shirt, red tie, and what seemed like a huge smile! When I went back to that dealership, I recognized where we took delivery of the car, even though a lot of the dealership had been remodeled/expanded. I was 2 ½ back then and remember all of it!!! When I went back to the dealership in 2022, I got pictures of the area. I also went over to OPGI around the corner from there and got some pictures of their 1966 SS396 that had some unique options. That helped me locate and install some of the items back where they should be in my car!

After taking delivery of the SS396 on August 11, 1966, we immediately made our way over to Disneyland, and even saw Walt himself, with his crew, greeting folks on the train. We then headed East, after tanking up with Union 76 gas (got the card, and of course the antenna ball that I watched as we went across the country). Dad’s favorite picture of the SS is still the one of it parked at the South rim campground (we roughed it there) with the canyon in the background.

Through the years, the SS was our main family car, taking us back and forth up the East Coast, and finally taking us out to Albuquerque, New Mexico in 1968, just before dad went back to Vietnam for his 2nd tour. It was during that time, just right after the warranty expired in 1969, the 396 ate a valve, leaving my mom and the two of us first graders stranded. My uncle and his friend (mechanic) repaired the engine by sleeving it and keeping the original block! I have the letter he wrote to dad in Vietnam outlining the work/cost of what they did. Mom also wrote dad a letter, threatening to burn the car down for leaving us stranded, which got dad to act as soon as he got home, to find mom a second car for her to drive (A 1970 Maverick, 6cyl. That’s a whole other story.). To this day, and as of this writing, mom (92 years old) still doesn’t like the SS, and still is amazed on the money/time that I spent restoring it! She did soften though and kicked in some money to help with the restoration.

Dad retired from the Marines in May 1974, and he purchased a 1972 Prowler 20ft, double axel travel trailer (towed by the SS) to take us on a cross-country adventure from North Carolina, to Canada, and diagonally across the US, ending the journey back in Albuquerque again. He wrestled with the carburetor and burned a clutch on the way out, but it was a memorable adventure. He had CBs in the SS and the Maverick, so we were able to ‘convoy’ across the country.

Fast forward to 2017, Dad and I had planned to restore the SS, which had been sitting in his back yard in front of the 1972 Prowler RV Trailer, and 1973 Suburban with a 454 for quite some time. Dad said a while before, “When they tell me that I can’t fly anymore, we’ll start working on the SS.” Dad loved flying. He flew in the Navy, Marines, Search and Rescue, and finally in the Civil Air Patrol. Dad flew up until the month before he passed at age 86. None of the men in his family lived past 67, so he truly blazed a new path there too.

In May 2020 when Covid was in full bloom and the world was shutting down, I decided that starting the restoration of the SS would be good therapy, and a distraction from all that was going on at the time. I have done some minor restoration and wrenching on cars through the years, but never an all-out, frame-off, last nut and bolt adventure! I have been watching Gearz for quite a few years and have enjoyed the episodes, '32 Roadster, Stunt Double, Sgt. Rock, Pro-Touring Cougar, Ted Nugent’s Bronco, and of course, the Catalog Camaro (My High School buddy’s 81 Z28). So here I go, just jump in and get my hands dirty!

A longtime friend (Lil John Harvey, paint and body man from LA) took the body off the frame and let me haul back the rolling chassis to my little garage. From there, Lil John had the body blasted, painted the original color (Chateau Slate) in ~2months, and left it covered on the rotisserie while I started dismantling the rolling chassis. Dear friends loaned me the assembly manual, and I also had the manuals from dad (He saved everything!). Before I took anything apart, I took as many pictures as I could so I can leave breadcrumbs on how it went together originally, and I also found that dad saved parts he took off the car, like the original Holley 4160 ‘California smog carb’, and the original AIR pump for the smog device that dad had never taken off! All were found, documented and pictures taken! Anytime something was taken apart, I would look for serial numbers and part numbers to confirm that the car had never been apart since the day dad drove it off the lot. If I could not refurbish the part, then I would order the new part to replace it. Some items were not available on the reproduction market due to their rarity, so some in-garage reconstruction had to happen. Taking the engine apart proved to be a whole new adventure that my wife helped me do out there in my driveway late one night. Dawn has been with me for coming up on 40 years now and has been there during some of the most challenging times in my garage! Before the SS, she helped me install a gas tank in my Olds. She bench-pressed that in place while I got the bolts started! Dawn helped me take the SS’s engine/transmission out of the frame and helped me to get it back in once it was back together. Another good friend, Keith Adelsberg (Of Impala SS427 fame) walked/talked me through the entire engine build, working with Mark Jones (VortecPro) who did the complex machining/foundry work to save the original 396 block that was cracked back in 1969!

We finally got to the finish line, and once we got the body back on, I had the SS hauled it down to my high school buddy, Jim Guthrie @ Guthrie’s garage, because he had the tools/expertise to handle the final items with the frame/suspension and firing it up for systems functionality. Once finished, the first place I took it was over to mom’s house for her to look at it. Even at 92 years old, she was most amazed at the Star Trek themed magnetic mini ashtray that I restored from the dealership that dad left on the dash as a reminder of when mom used to smoke! Every time I drive my dad’s car, a new memory comes to mind, and of course, it’s my true time machine to take me back to 1966!!

Season 19: Episode 3

Cory Haberkamp | Roseville, OHThis project began with ideas I’d wanted to implement from years of magazine articles, many summers on a tractor, junk from around the farm, and a couple TikToks from a college buddy.

Being more budget friendly than conventional 4x4 platforms, along with the inherent uniqueness of this build, appeals to both me and my kids. The challenge of fabricating a 1200lb rig on 42” tires also appeals to the kid in me, harkening back to monster trucks of my childhood.

Plans for the build include an AMR500 roots style blower, 5.38 gears, and I’m currently adding four-wheel steering. This should wow spectators at local parades, as well as anyone out on the trail.

The only parts original to a lawnmower are a Briggs and Stratton 16hp opposed twin engine and the original body. Initially I’d constructed a ladder frame and utilized the original peerless transaxle. It was short lived, and I replaced it with an automotive transmission. I’ve since upgraded yet again to a 1-5/8” chromoly tube chassis and an AX5 Jeep Wrangler transmission to feed the Suzuki Samurai axles. The front steer axle is flipped to work with the NP231 transfer case, while cut and flipped 1/4 elliptical Jeep YJ springs hold everything up. With the 42” powered implement tires, this monstrosity boasts ground clearance of 15” under the differentials.

Season 19: Episode 2

Steve Lindmark | Minden, NVMy 1st vehicle was a '52 Studebaker pickup when I was 19. Now I am retired and had a 1000 sq ft shop built in my backyard. I found a '52 Studebaker pickup in southern Washington that wasn't running and decided it would be my retirement hot rod. I am using a '94 Dodge Dakota chassis, a crate LS3 drivetrain with a 6L80E six speed trans, and a Ford 8.8 rear end. One night, a cordless lithium battery on a charger failed, and burned down my shop. The Studebaker was parked next to the shop and was charred down the driver's side. As I work towards having the shop rebuilt, I decided not to let this tragedy stop my dream. I purchased another Dakota (not running), this one a '95, as my next chassis donor. I’m starting over when the new shop is finished. 45 years of tool and equipment acquisition gone in the fire, but I won't let that stop me!

Season 19: Episode 1

Tyler Tippelt | Milton, WIOne day, the idea popped into my head that I really wanted a Checker Marathon, and I wanted to build it into a true gasser (the first in the world to my knowledge). I’ve always been intrigued by the A11/A12 Checkers and loved the utilitarian look about them. They look like someone blended a ‘58 Chevy and a ‘58 Rambler together, except using all the worst parts. A few months after I had the idea, this basket case of a one-owner, non-taxi ‘73 dropped into my lap. After some haggling, I got the car for $900 and the TH400 that was in it, even got the original title from ‘73!

Once I got it home, I realized I now own one of the worst Checkers that still had 4 wheels.

The driver’s side frame rail had rotted in half just under the toe board, along with the coil spring jutting up through the bucket. Even the steering box had ripped out of the frame. Body wise, the exterior shell was decent, as in, everything was there. The floors, however, were rotted, patched, and rotted again.

Knowing the pile of work ahead, I just started plucking away. I braced the body and removed it from the chassis. Luckily the rear ⅓ of the chassis was usable, meaning I only had to build the forward ⅔’s. Seeing as my plan is to build a gasser, I wanted a straight front axle. Also, I want to build it on a budget, so the Speedway axle kit for $500 was out. Instead, I found a 2WD XJ Cherokee axle for $150 and bought the “Nova” straight axle spring kit from Speedway.

With the plan set, I bought 8 feet of 2x5 .120 wall rectangular tubing and 6 feet of 2x3 .120 wall rectangular tubing and began to cut, mockup, cut some more, and weld up the tubing to form the new 70% of the chassis. This was the first heavy fabrication project I’ve ever had, so I took my time and advice from those smarter than me to build the chassis. Next was to hang the axle; using the rear end, I squared the front axle at the 120” wheelbase, set the springs up and welded the perches in to have an initial caster measurement of 10 degrees.

Drivetrain wise, I knew I wanted a Big Block Chevy and a 4-speed. I picked a Gen IV 454 up for $600 and was pleased to see it has 781 heads. I was less impressed when I tore it down to see the cam wiped, an improperly aligned thrust bearing, and the #1 rod journal on the crank that had self-machined at least 0.10” off it. At least I could use the block to mount the motor plates in the chassis!

Keeping with the budget, I found a Borg Warner Super T-10 from a mid-70’s F-body (w-code ratio) for $400, a Lakewood scatter bellhousing for $150, and a set of good Eagle H-beam rods with 0.060 over SRP +10cc forged pistons for $500. I want the big block done right, so I’m taking my time to have it machined and collect parts as my budget allows. Ultimately, it will be a 10.0:1 468 cu in with a tunnel ram and a matched set of 1850 Holley 600’s that I found for $125. For the time being, I’ll run my AFR headed 350 in it with the corresponding front motor plate as a shake down power plant.

Now onto the body. Wanting the gasser look with wide meats out back, I bought a set of Tri-5 Chevy radiused wheel arches and patched them into the rear quarters, taking care to blend the lip of the arch into the factory bodyline that formed the original wheel opening. I also had to hand form a lot of patch panels, ranging from small to the entire upper edge of the right rear quarter. With the looks coming along, it was time to tackle the floor. Knowing that I couldn’t do the job myself, I towed the car to my friend’s garage, and we began regretting almost all our life decisions. We decided to brace the body further and cut the entire floor out along with what was left of the inner/outer rockers. My buddy then hand-made hat channels and inner rockers, I fabricated inner kick panel replacements, and we got to work setting the body in its final location before building the floor structure. We made the floor out of 3 pieces, a full sheet per side, formed and bead rolled, with a custom tunnel made in my buddy’s metal brake. For the first time in at least 30 years, the car’s body was solidly attached to the chassis.

The time came to bring it home and get it to its current state. I finished the rear of the floor and fabricated new inner side panels for the rear along with a custom “gasser” style hood scoop. It’s been a pile of work, but it’s been absolutely worth it to save this car from the crusher. I’ve made this much progress in 8 months while also working my day job as an over the road trucker, and I’m fairly confident it’ll fire up for the first time by January! The name of the car is “Fare Enough” inspired by the history of Checkers in the Taxi world, and the fact that I’m getting it built well enough to function safely and have fun without breaking the bank.

It’s still what I consider a budget build, I have about $4500 into the car at this point (including the purchase price), building basically from the ground up to a solid platform that just needs a simple fuel system, brakes, clutch setup and other minor trinkets.