The Latest

-

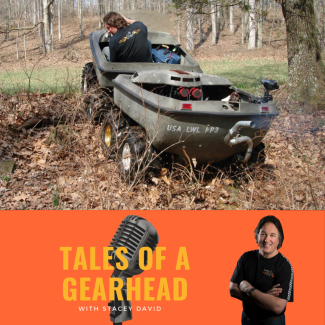

If you’ve watched Gearz in the past, you’re probably familiar with our little Thiokol IMP Snowcat project. Well, today you get to meet the legendary big brother…the Thiokol Swamp Spryte! What?May 08, 2024

-

No, this isn’t about the movie with crazy Jack chasing his family around, this is about paint!May 01, 2024

-

Last season Stacey rolled in a barn find 1967 Jeepster convertible and demonstrated how to do a Level 1 restoration on it by getting it running and driving again.April 24, 2024

-

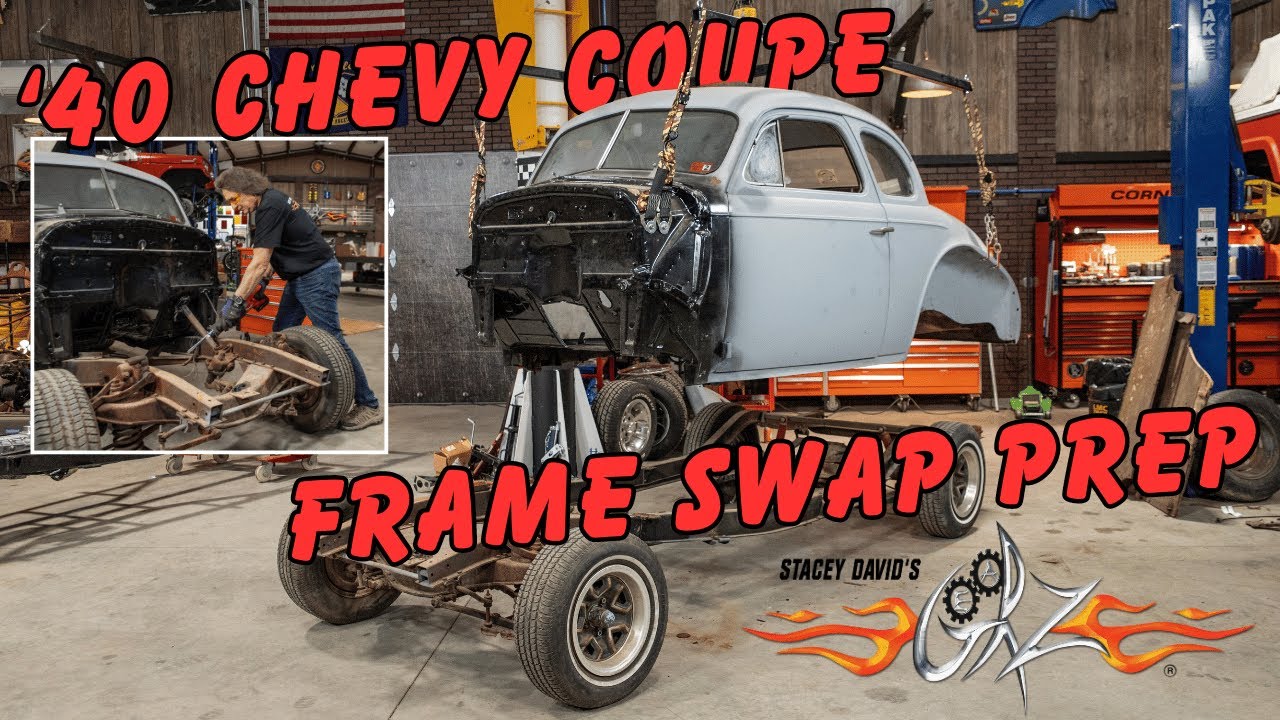

The Hot Rod Coupe is back in the shop as Stacey continues to fit the old ’40 Chevy body down on the new replacement frame.April 17, 2024

-

When it comes to working on a vehicle, nothing quite prepares you for the first time you pull a body off a frame. Even though it sounds easy, there is MUCH more involved than meets the eye.April 10, 2024

-

Watch the Jeep Gladiator go from stock to a fully outfitted search & rescue vehicle now for free!March 14, 2024

-

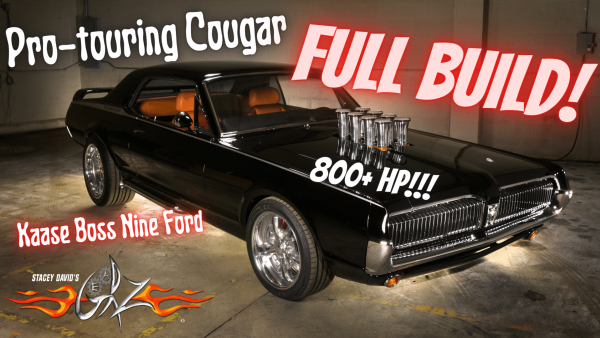

Watch the full build of the 830-horsepower pro-touring Mercury Cougar now ONLY on Stacey's YouTube channel!January 12, 2024

-

Everybody knows that if you have tools, you need to have a place to keep them.

October 25, 2023